I have been actively analyzing and criticizing the technical and other design solutions in SMR, especially, but not only the NuScale reactor and power plant project. My opinion being presented not only in SMR LinkedIn group but here in NuCon.US also and my own professional experience. Naturally, using open sources as references, with sources named below of each article. In particular, from the NuScale website, DOE etc. And yesterday I received a notification from so-called NuScale lower, and he is asking to remove pictures and the copy of presentations pages from some articles on NuCon.US blog, which related to NuScale source and the fact that I do not use them as I would like to the owner. Surprise-surprise…

Rather, they were waiting for praise and admiration, and they are not. Did I really break the law (DMCA) or it is a struggle with criticism? As an option, I consider excessive zeal of not smart people. Respond to criticism they do not want me to have too shallow, and the attempt to ban criticism is. By the way, this (same) message being instantly removed from the Platt’s SMR group in LinkedIn and I wonder why? Which reason? What is wrong here? Any thought? Just because NuSclae is Platt Conference sponsor.

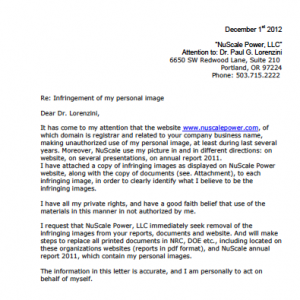

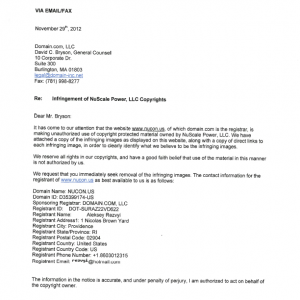

Sure… I will change all NuScale pictures in NuCon.US blog on the special note, temporary before I try to solve this problem. Probably, NuScale has nothing to do with design or do not have the capability, and they have a lot of time for this kind of activities. And looks like they are attacking me personally. Let’s see… I did find my personal images on NuScale website and did send them my letter as an answer. Do I need fight back? Just for fun I sent them this letter, and will present here the letter from NuScale:

If we consider the reasons/causes for which the reactor must be urgently taken out of operating (by scram cause), most of all, they should be divided into several different groups:

- Accidents and failures associated with the reactor’s core work/operating (rho, tau, neutronics power)

- Accidents and failures associated with the primary circuit operating (coolant outcoming high temperature and/or increasing primary pressure in the reactor)

- Accidents and failures associated with the reactor (coolant) leaks of different intensity (coolant level and internal reactor pressure decreasing)

- Accidents related to the turbine part (plant) faults (different reasons, technical or operatings), steam and feed-water (FW) (FW pressure and secondary steam pressure and temperature)

- Accidents related to equipment operating (electric power supply loss and/or failures of important machines, agregates, etc)

- Accidents related to crew operating errors and mistakes.

In amount, all we can consider about 12-15 signals, some of which somehow overlap. For each signal (or group), during scram and cooling process variously operated equipment, which can be used to transient mode power plant unit it to the emergency cooling regime. So, different ways and cooling, emergencies and long-term heat removal process. Let’s do some simple and pretty understandable overview:

- The first two groups have in common is that the power plant (reactor) has no the failure of major equipment and systems, and hence shutdown and heat dissipation can be made rapidly, but in a regular (standard systems and heat removing channels).

- The third group, which includes leaks reasons (small, medium, large, pipes break and/or LOCA), by a strange coincidence, and estimated the designers and inventors are partially not considered (?) for LW-SMR. Specially LOCA.

- The fourth group of the accidents related to faults pumps (FW or Condensate pumps), main condenser (MC), main turbine, pipes breaking off, valves, problems with feed water supply and steam distribution.

- The fifth group related to the blackout not only failure of major equipment (see fourth group), but also to the complete loss of control over the power plant operating and is more worst fourth variant.

- And the sixth group, which we are not discussing here.

So, before we found out that for the safe shutdown procedures (algorithms) of the power plant (reactor) need several heat removal ways (channels). While we do not consider the circulation of primary coolant yet, which is a separate and very interesting point of discussion.

The first channel (normal heat removal process) is the way to drop the steam, steam-water mixture or water (in various regimes) from the steam-generator (SG) through the steam pipes, to the MC. In this case, starting-up feed-water pumps and condensate pumps are working normally, also. And, feed-water going through SG, after going into the MC with pre-wet steam with cold water. Then transient to steam-water mixture regime, and in the end only heating water regime. Electric power connected normally and available, all the power plant supporting systems working normally, also. Residual heat peak removal process is not difficult after this types of scrams. The reactor will be transferred to the normal cooling mode without any problem.

The second channel, if steam lines/pipes has being damaged, SG or condensate – feed-water system, and the MC and/or main cooling system. In this case we need a special backup heat removal channel. In the design variant types like NuScale DHRS (or CAREM (?) for example, etc) it is dropping steam and/or steam-water mixture from the SG to the separate and special heat exchanger (HE) submerged in the huge pool behind the containment and in the organize of a natural circulation (NC) pattern SG-HE. Except for the calculations, in theory there is probably no problem. But once there is a number of questions: What about the level of the primary circuit (again?). And containment when working constantly immersed in the pool? The second question is not so important, probably safety automatically increase if we will put reactor in the pool (sarcastic). But the first question still to be really important. Without a detailed explanation, this is still to be design problem. And US Patient 80,170,173 not actually exist in project any more? O-ops…

Surprise, surprise… we will talk about third way below. Lot of interesting stuff we can find about design’s conception here. The third channel of heat removal be connected up during the most heavy accidents. Organization of cooling water from the water-filled reactor’s containment, to the reactor lower plenum. Is this possible in/with open circulation loop, when the coolant evaporating through pipes with valves on top of the reactor vessel? Evaporated coolant is condensing on the cooled containment walls (which submerged into the pool), the water pour down to the containment bottom. Where, through the open “circulation” pipes with valves (same like on top) falls into dropping the reactor again to the core from bottom, going through the core, heating, partially vaporized and then through the top part of the reactor going out into containment again. Looks good. In theory yet.

Quite a strange scheme CHRS and in terms of engineering reliability and in terms of the heat sink from the core. In terms of equipment fault (turns out) that in addition to the pressure relief/vent steam valve (or two), there are several individually controlled valves (probably, at least 8) on large enough diameters pipes, connecting the internal volume of the reactor with containment cavity (O-ops!!!). Probably 4 on top and 4 below in lower plenum area, just right after the SG (see p. 40 also ).

This design solution is so uncertain and does not hold water, in terms of reliability, and that discussing it “into the air” with no opponents responds not possible. There’s even no LOCA not talk about the absence of which so confidently say the designers of the reactor and this kind of system (sorry, but NuScale again). Interesting to see calculations algorithm. But with opponents, it would be fun to argue. Indeed, there is no connections and target definitions, and several pipes is out, valves faults, well, come off … It happens to everyone.

Again, there is an interesting question for our heat removal from the core and the organization of the primary circulation loop. The truth, in this case, the primary coolant level in the reactor “lost”, and we can not to say exactly, what is going on with the reactor core. What are the risks, designers must also consider.

And, for this kind of design and this kind of technical solutions people can get Government grants? But we are still talk about economy of the SMR here…

(For additional information: www.NuScalePower.com and presentations)

Virtually all of the LWR SMR designs submitted to NRC and DOE in the US demonstrate connections for fuel loading/refueling on the upper level of core’s “pan” (bottom part of reactor vessel). Can someone explain how and who/what will ensure the monitoring of the compound deep undo the bio-protection shielding. And besides, in the pool, as it is shown in a promotional video NuScale, for example. How to ensure purification water to such an extent and volume?

In the USSR, and in Russia, the lid of the reactor is connected to the vessel via a special ring and through the so-called “extended (?) studs.” Before tightening the nuts, each stud stretches hydraulic jack to provide tightening, not only with the power hydraulic tool.

What is the procedure at the reactors of “western” design? How to ensure the connection density and construction, strength of the connection if there is no human’s access to the area? Strange, but I do not believe in the complete automation of the process in the “pool”.

(For additional information: www.NuScalePower.com and presentations)

Animation: http://www.nuscalepower.com/video_loading.php

The mPower design, a 125-MWe concept under development by Babcock & Wilcox, also features passive cooling, but “our whole principle of safety is defense-in-depth,” said Jeffrey Halfinger, B&W’s vice president of technology development. He spoke at the conference and was interviewed after his presentation.

The concept of defense-in-depth, he said, is to have “multiple stages” of cooling and backup cooling systems before the reactor resorts to passive cooling, which is the emergency measure. Under the emergency situation, Halfinger said, operators can replenish the water tank that feeds the passive cooling system, which can keep running “for weeks and weeks and weeks.”

- This is interesting, but no detailed information from mPower.

There are “few accident scenarios” in Westinghouse Electric’s unnamed SMR reactor concept, said Michael Anness, manager for advanced reactors at the company. “There are no active safety systems in the [Westinghouse] small, modular reactor,” he said at the conference.

The smaller design has fewer penetrations of its reactor and containment vessels, fewer valves and fewer pumps, Anness said.

- It is very informative of cause.

The design of the company’s SMR reflects some additional passive safety features incorporated into its 1,100-MW AP1000 unit, which is under final review by the NRC for design certification, Anness said. More safety, it turns out, does not mean more pipes and backup pumps and valves, he said.

From: http://www.platts.com/RSSFeedDetailedNews/RSSFeed/ElectricPower/6126955

William Freebairn (william_freebairn@platts.com)

Yanmei Xie (yanmei_xie@platts.com)